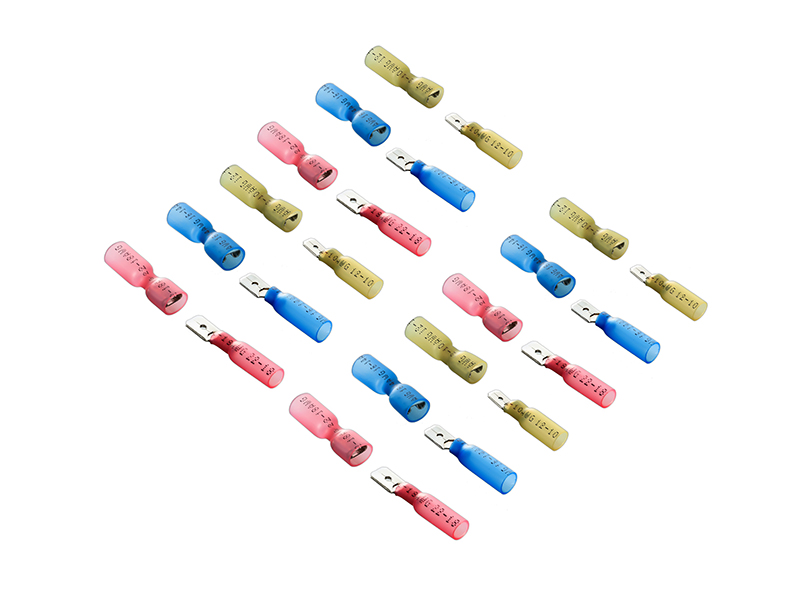

HSFT HSMT Heat Shrinkable Terminals

HSFT HSMT Heat Shrinkable Terminals

Applications

HSFT and HSMT are heat-shrinkable sleeves made of polyolefin and hot melt adhesive. They are used for protection connection, waterproof and anti-corrosion. It can strengthen the fixing and anti-vibration in a rough environment. It has a good function of insulating and protecting the electronic connector. Durable, easy to install, and low installation cost compared to conventional connectors.

Characteristics Shrinkage ratio 3:1 Excellent stretch and mechanical damage resistance Ideally translucent provides tensile strength High elasticity keeps steady performance | Operating temperature range Operating temperature : -55℃~125℃ Minimum shrink temperature : 80?C fully recovery temperature : 130?C |

Technical Indicators

Test Item | Characteristics | Test condition | |

Unaged | Tensile strength | Min. 16MPa | Room temp. |

Elongation | Min. 200% | ||

Aged | Tensile strength | Min. 11.5MPa | 136℃/7 days |

Elongation | Min. 100% | ||

Voltage withstand and breakdown Voltage(Unaged) | Withstand 2.5 KV for 1minute and breakdown | Room temp. | |

Voltage withstand and breakdown Voltage(Aged) | Withstand 2.5 KV for 1minute and breakdown at least half of unaged breakdown voltage | 136℃/7 days | |

Copper corrosion | No corrosion of bare copper | 136℃/7 days | |

Copper stability | No sign of degradation Min.Elongation 100% | 136℃/7 days | |

Cold bend | No crack | -30℃/4 hrs | |

Maximum secant modulus(2%) | 250 MPa | - | |

Volume resistivity | Min.1014Ω-cm | - | |

Heat shock | No crack | 200℃/4 hrs | |

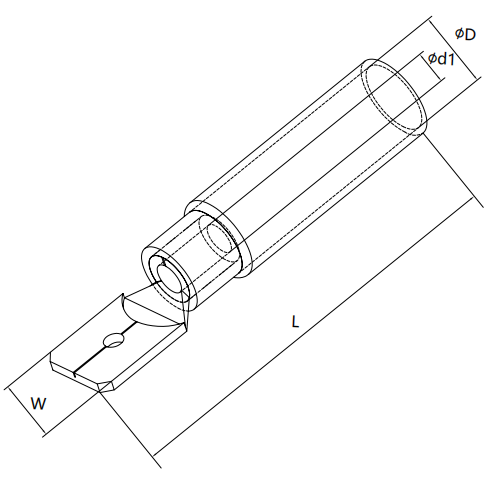

Product Dimensions-HSFT

Part. No |

Wire Range |

Tab Size(mm) | (mm) | Length(mm) | Insulator | Color | |||

A.W.G | mm2 | Size | d1 | D | W | L | |||

MDD 1-250 | 22-18 | 0.5-1.0 | 6.3 x 0.8 | 1.8 | 4.7 | 6.3 | 31 | PE | Red |

MDD 2-250 | 16-14 | 1.5-2.5 | 6.3 x 0.8 | 2.3 | 5.7 | 6.3 | 31 | PE | Blue |

MDD 5-250 | 12-10 | 4-6 | 6.3 x 0.8 | 3.5 | 6.7 | 6.3 | 33 | PE | Yellow |

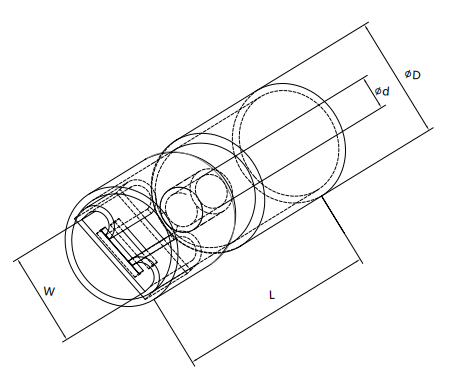

Product Dimensions-HSMT

Part. No |

Wire Range |

Tab Size(mm) | (mm) | Length(mm) | Insulator | Color | |||

A.W.G | mm2 | Size | d | D | W | L | |||

FDFD 1-250 | 22-18 | 0.5-1.0 | 6.6x 0.35 | 1.8 | 7.0 | 6.6 | 29 | PE | Red |

FDFD 2-250 | 16-14 | 1.5-2.5 | 6.6x 0.35 | 2.3 | 7.0 | 6.6 | 30 | PE | Blue |

FDFD 5-250 | 12-10 | 4.0-6.0 | 6.6x 0.35 | 3.5 | 7.0 | 6.6 | 32 | PE | Yellow |