熱縮圓形端子

熱縮圓形端子

應用

HSRT是由聚烯烴和熱熔膠復合生產而成的熱收縮套管,用于保護連接、防水防腐蝕,可以在粗糙的環境中加強固定和防震動,具有很好的絕緣保護電子連接器的功能。與常規的連接器相比,具有耐久性、易于安裝、安裝成本低的優勢。

特性

收縮率3:1

材料優異的延伸性能,抗機械損害

透明度佳,提高更好的抗拉力

高彈性能,管材不易變形

操作溫度范圍

操作溫度: -55℃~125℃

開始收縮溫度: 80℃

最低完全收縮溫度: 130℃

性能參數

Test Item | Characteristics | Test condition | |

Unaged | Tensile strength | Min. 16MPa | Room temp. |

Elongation | Min. 200% | ||

Aged | Tensile strength | Min. 11.5MPa | 136℃/7 days |

Elongation | Min. 100% | ||

Voltage withstand and breakdown Voltage(Unaged) | Withstand 2.5 KV for 1minute and breakdown | Room temp. | |

Voltage withstand and breakdown Voltage(Aged) | Withstand 2.5 KV for 1minute and breakdown at least half of unaged breakdown voltage | 136℃/7 days | |

Copper corrosion | No corrosion of bare copper | 136℃/7 days | |

Copper stability | No sign of degradation Min.Elongation 100% | 136℃/7 days | |

Cold bend | No crack | -30℃/4 hrs | |

Maximum secant modulus(2%) | 250 MPa | - | |

Volume resistivity | Min.1014Ω-cm | - | |

Heat shock | No crack | 200℃/4 hrs | |

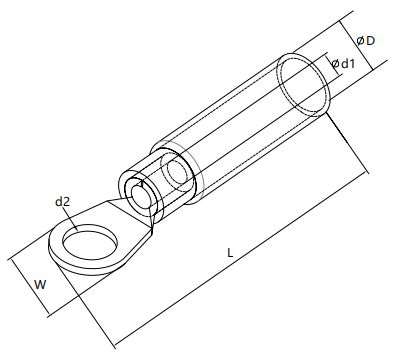

產品規格

Part. No |

Wire Range |

Stud Size(mm) | (mm) | Length(mm) |

Insulator |

Color | ||||

A.W.G | mm2 | Size | d1 | d2 | D | W | L | |||

RVS 1.25-5 | 22-18 | 0.5-1.0 | #10 | 1.6 | 5.2 | 4.7 | 8.0 | 31 | PE | Red |

RV 1.25-6 | 22-18 | 0.5-1.0 | #1/4 | 1.6 | 6.2 | 4.7 | 11.6 | 36.5 | PE | Red |

RV 1.25-8 | 22-18 | 0.5-1.0 | #5/16 | 1.6 | 8.2 | 4.7 | 11.6 | 37 | PE | Red |

RV 1.25-10 | 22-18 | 0.5-1.0 | #3/8 | 1.6 | 10.3 | 4.7 | 13.6 | 37.5 | PE | Red |

RVL 2-5 | 16-14 | 1.5-2.5 | #10 | 2.2 | 5.2 | 5.7 | 8.5 | 31.5 | PE | Blue |

RV 2-6 | 16-14 | 1.5-2.5 | #1/4 | 2.2 | 6.2 | 5.7 | 12.0 | 36.5 | PE | Blue |

RV 2-8 | 16-14 | 1.5-2.5 | #5/16 | 2.2 | 8.2 | 5.7 | 12.0 | 36.5 | PE | Blue |

RV 2-10 | 16-14 | 1.5-2.5 | #3/8 | 2.2 | 10.3 | 5.7 | 13.6 | 39.5 | PE | Blue |

RVL 5.5-5 | 12-10 | 4.0-6.0 | #10 | 3.4 | 5.2 | 6.7 | 9.5 | 35 | PE | Yellow |

RV 5.5-6 | 12-10 | 4.0-6.0 | #1/4 | 3.4 | 6.2 | 6.7 | 12.0 | 39 | PE | Yellow |

RV 5.5-8 | 12-10 | 4.0-6.0 | #5/16 | 3.4 | 8.2 | 6.7 | 15.0 | 44 | PE | Yellow |

RV 5.5-10 | 12-10 | 4.0-6.0 | #3/8 | 3.4 | 10.3 | 6.7 | 15.0 | 44 | PE | Yellow |